Tekelek has over twenty eight years of expertise in level measurement and control design and manufacturing. We are industry leaders in level measurement technology monitoring solutions. Tekelek’s range of reliable innovative measurement technologies provide continuous level measurement for tanks, silos, mobile tankers, IBCs, totes, drums, barrels and a variety of other storage containers. We pride ourselves on our ability to meet changing customer needs and technologies. Here are some prime examples of our work.

WiFi & CAT-M1 in the US

Partnered with an Asset Management company active in the Oil and Gas market in the US.

- fuel oil and propane monitors across a wide customer base

- offers client visibility to end customers fuel oil/gas levels

- enables development of an ecommerce element to market special offers and target specific demographics.

- delivering a minimum of 20% improved operational efficiency

Tekelek has recently developed a 4G NB-IoT CAT-M1 version and an intrinsically safe 4G NB-IoT CAT-M1 sensor to facilitate the expansion of the company.

Tekelek LoRa ultrasonic sensor in water monitoring

Partnered with international humanitarian aid agency mandated to protect refugees and displaced peoples. A key function of the aid agency is to keep refugee camps supplied with water. Managing the delivery of water to these camps is critical to make sure adequate supplies are in place as well as making sure that the delivery companies are performing to agreed terms.

Tekelek LoRaWAN liquid level sensor was an ideal choice in this task.

- Cost effective, reliable measurement, together with the exceptional range of data transmission exceeded expectations.

- Data from the sensor has been incorporated into their systems, making sure that there are always adequate supplies of water in place and allowing delivery schedules to be planned to make sure there are no run-outs.

- Cross referencing with the billing from the water delivery companies has the added benefit of being a very cost effective auditing tool.

Tekelek GSM ultrasonic sensor in the chemical industry

Partnered with a major US international marketer of maintenance products with a focus on specialty chemicals, industrial maintenance supplies, pet products, and plumbing parts. Managing and tracking mobile assets for inventory distribution was a challenge. The TEK733, GSM based ultrasonic sensor incorporating GPS functionality was identified as the optimum solution Tank contents are measured using Tekelek ultrasonic technology and transmitted, together with GPS information, over the GSM network to the company server.

Solution

- Real time visibility to tank contents, and locations helped optimize operational efficiencies and bottom line profits

- Accurate data has enabled Sales teams to better service customers and better manage orders.

- Ongoing system development with the ultimate goal of automatic order generation based on data from the monitors.

Tekelek GSM ultrasonic sensor in the equipment rental sector

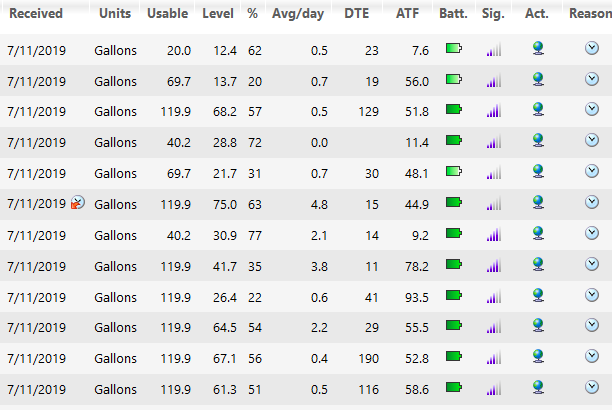

Partnered with leading specialist in the Gulf Region supplying a range of solutions from product sales, equipment rental to turnkey project execution. Reducing dependency on site-based supervision and manual monitoring is critical to optimize project operational efficiency. To achieve this, the company developed a remote monitoring system which can monitor and manage pumps and systems. However, a sensor was required to feed data into this system on the status of fuel tanks on remote diesel power generators. The proven reliability, performance and cost point makes the TEK733 GSM Tank Sensor an ideal choice for the application.

Integrating with Company’s Remote Monitoring System

The system provides a view of the status of the full population of tanks, clearly identifying tanks that require servicing, as well as usage rates on individual tanks. The information is used to manage replenishment cycles of the tank and improve operation efficiency by optimising delivery routes and site visits.

Partnered with leading specialist in the field of pumps, water management and water treatment in Dubai.

- Facilities Management applications

- Diesel generators, watering / de-watering applications

- Utilising real-time data on fuel level and asset location

- Minimum 20% improvement on operational efficiency

Tekelek propane monitors in the propane delivery sector

Partnered with an Asset Management company active in the Oil and Gas market in the US.

The company identified the need for companies to address their cost base by optimising delivery routes and began looking for cost effective technology that would give fuel delivery companies visibility to their tank contents. The TEK822 propane monitor from Tekelek was the optimum choice.

- Fully certified as intrinsically safe making it suitable to connect to propane tanks fuel oil and propane monitors across a wide customer base.

- Certified for operation on the AT&T and Verizon networks in North America providing excellent coverage all over the US.

- Offers client visibility to end customers fuel oil/gas levels.

- Enables development of an ecommerce element to market special offers and target specific demographics.

- Delivering a minimum of 20% improved operational efficiency.

Tekelek monitors in waste bin monitoring

Partnered with principal French waste management company in the management of solid or liquid non-hazardous or hazardous waste.

The waste management company sought a monitoring solution to accurately monitor and report on fill levels of municipal waste bins to drive improvement in its recovery operations.

Tekelek adapted the standard LoRa level sensor to refine the ultrasonic performance and mounting method to make it suitable for waste applications.

- Ability to monitor full population of bins in a reliable and cost effective manner.

- Data is used to adjust operational practices to only service bins that are full driving significant improvement in operational efficiencies and customer service.